Article

All goods — from medication and food to smartphones and automobiles — must meet quality control (QC) requirements. As products go through the production, teams must keep an eye out for issues that could compromise product quality and safety, such as misassembled products or missing components, defects in raw materials or completed products, or malfunctioning machines or production assets.

Most companies address quality control issues using numerous manual processes that require a lot of time and human resources — which significantly increases production costs and doesn’t always lead to the most accurate results.

However, quality control teams can do their jobs more efficiently with AI as an assistant. AI lets them tackle Quality Control issues with less time and effort.

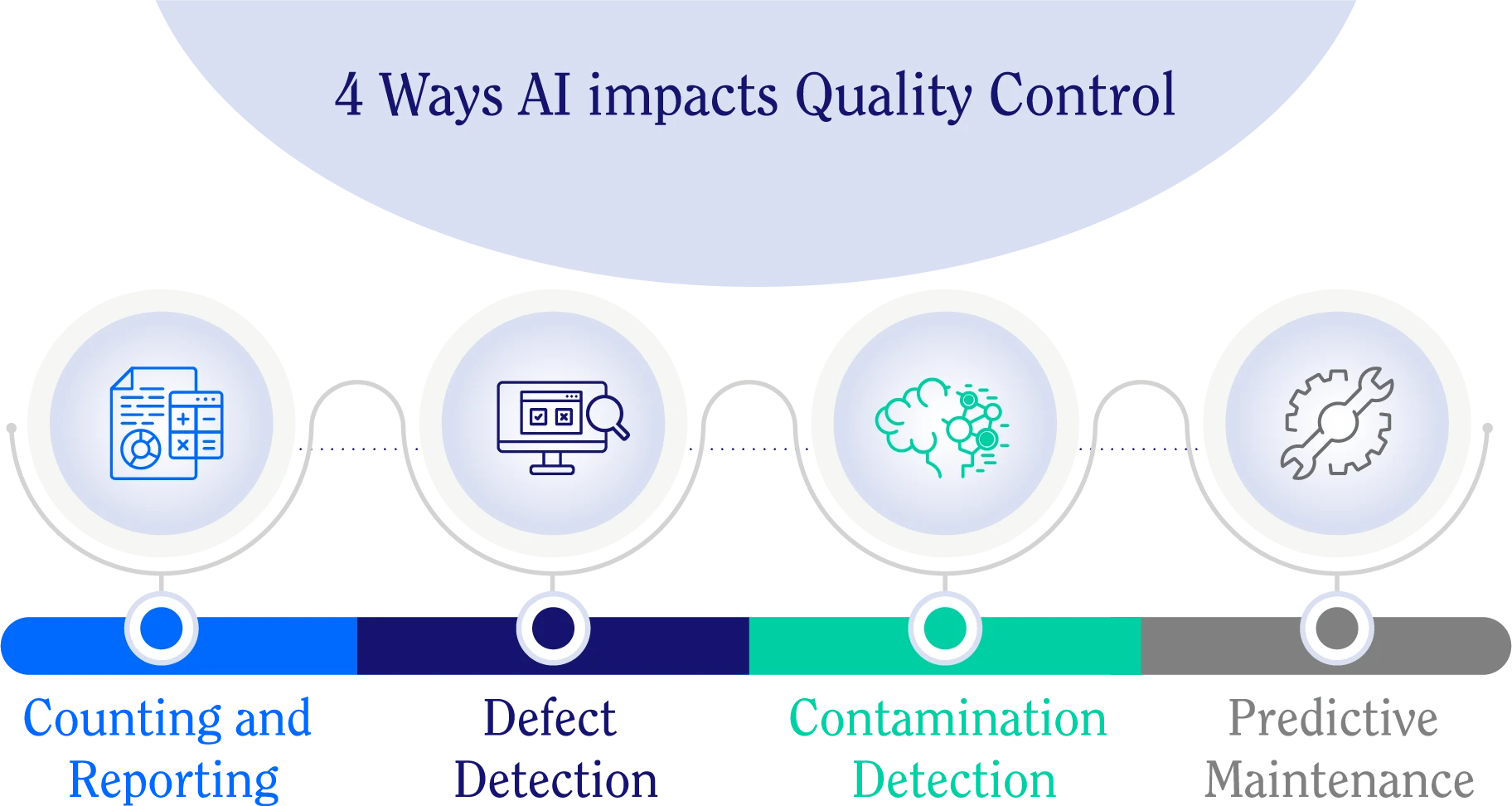

How AI improves quality control?

You can apply AI throughout the entire production process, using it to assist QC teams with a wide range of tasks.

1. Counting and reporting

Producing a vaccine is a complex process where lab technicians must do many tedious and repetitive tasks. For the lab technicians at GSK, one of those tasks is colony-forming unit (CFU) counting. The team must accurately count the number and type of CFUs to ensure that the growth process for the proteins proceeds correctly. If the team makes any counting or annotation errors, they could produce an inferior or ineffective vaccine.

We worked with GSK to create an AI application that optimizes the CFU counting process and allows users to create custom reports.

At GSK, lab technicians spend up to 6x less time on CFU counting and reporting with Superlinear's AI solution.

2. Defect detection

No company wants to put defective products on the market. However, detecting defects in products is incredibly challenging, as many flaws are difficult for the human eye to see. For example, a human would have difficulty noticing missing screws or springs in a smartphone circuit board. Also, many companies produce so many products that it is impossible for teams to inspect each one visually. They instead must inspect a sample of products to estimate product quality.

AI can automatically identify potential defects that humans have difficulty seeing and inspect products at speeds faster than humans can achieve. McKinsey estimates that AI-based visual inspection can increase defect detection rates by as much as 90% when compared to human inspection.

3. Contamination detection

Contaminated products can threaten the health and safety of consumers, so detecting contamination is a crucial step in Quality Control. If you produce food products, for example, you wouldn’t want to expose consumers to parasites, chemicals, or insects. A 2011 study found that the average cost of a recall for a food company was $10 million — imagine the average cost today.

Detecting product contamination is challenging because the human eye cannot detect many forms of contamination. However, companies can automatically detect contamination the human eye can’t see using deep learning and computer vision. Once detected, teams can immediately take steps to prevent contaminated products from reaching consumers.

4. Predictive maintenance

You can’t mass-produce high-quality products without well-running machinery, making machine maintenance a critical part of Quality Control. It is simple — if a machine starts producing goods that need to be reworked or scrapped, quality goes down, and production costs go up. Reworking a product often means buying more raw materials or components and allocating more labor to restore its quality. You need to monitor and detect problems with machines before they start to fail.

AI lets you analyze data from numerous sources — e.g., sensors, SCADA, PLCs, ERPs — to predict potential problems with machinery and production assets. With this AI-assisted analysis, you can avoid unexpected downtime by promptly scheduling maintenance or repairs. And unplanned downtime is costly — the world’s largest manufacturers lose an estimated $864 billion per year to unplanned downtime.

Recap: How AI improves quality control?

We’ve highlighted several ways that you can use AI to improve Quality Control, but you can find many more:

Automatically receive alerts when environmental conditions change in a way that could cause machinery or assets to work inefficiently or even fail.

Analyze live closed-circuit TV images to detect potential contamination risks arising from lab technician or worker movements and behaviors.

Automatically generate relevant quality control documents and reports proving to auditors that processes and products meet regulatory compliance.

Streamline and automate processes to speed up drug production while also ensuring products meet Critical Quality Attributes (CQAs)

AI: The ultimate quality control assistant

AI assists teams in numerous ways so that they can perform their quality control duties better. It complements human skills and expertise, completing tasks at speeds humans can’t achieve and seeing things human eyes can’t. With AI, teams can closely examine and understand errors in quality control while also having the space to verify the accuracy of AI tools.

author(s)

Kristien Verreydt

Solution Lead